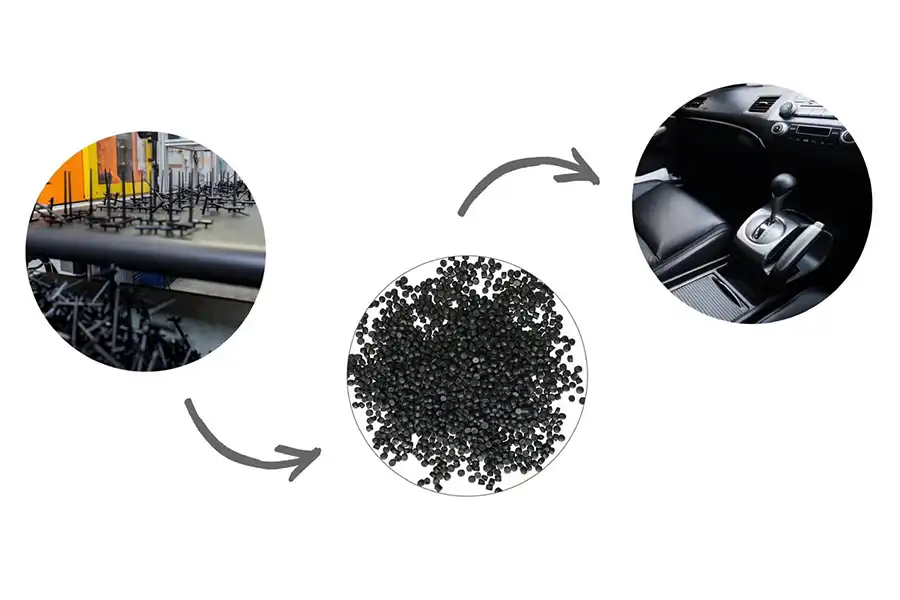

Plastics are essential and sustainable materials that are used in our daily life. Many of these plastic products are made of various compounds. Due to the many properties of compounds, many industries use them in the production of consumer products in a wide range.Polymer compounds are one of the most widely used and applied polymer materials in the chemical industry, which are used to increase the strength and stability of plastic materials.In fact, these compounds, which are a combination of polymer and a kind of powder, are used to strengthen polymer structures. By using this method, the application of granules in industries increases and compounds that have less weight, more durability and more efficiency are created, which are used as raw materials for other industries.In this article, we tried to examine the application of compounds in industries. Follow us to understand the use of compounds.

What is a compound?

Compound refers to a type of polymer material that some additives are used in the plastic injection process to increase its physical, chemical and thermal properties, and it can be produced in different grades. The application of compounds in industries is due to properties such as high flexibility and increased strength and resistance for the preparation of polymers and their use. In general, compounds consist of three components, polymer base, compatibilizer and additives, which are responsible for improving the properties of granules. The most effective ones in the compound production process are polymer base and additives. Additives maintain the performance and properties of materials. Some of the most common additives include the following:

- Fillers: These additives are used to improve durability, strength and dimensional stability. Among these fillers, we can mention calcium carbonate, talc and soil. In addition, adding these materials to the base polymer increases their thermal resistance and process control. Also, due to the cost-effectiveness of these additives, many manufacturers use them in the final products to reduce the production price.

- Colors: In this particular additive, the selected color can be different according to the polymer used, because these two combined materials must be compatible with each other, and its purpose is to change the color of the final product. To create different colors in the compound, mineral and organic colors, dioxide, black carbon and titanium are used.

- Antioxidants: Antioxidant additives are added to the final product to prevent the deterioration of plastics and increase their durability and lifespan, because plastics degrade when exposed to sunlight, and this degradation leads to color change, brittleness and losing some of its physical properties. Examples of antioxidants include phenols, arylamines and phosphates.

- Flame retardants: This type of additive is used to increase the compound’s resistance to fire and heat. These inhibitors can be combined with base polymers or added to the polymer during the plastic processing stage or added as a surface layer on the final product. The most common use of these materials is in electrical products because it prevents plastics from burning and being used. Phosphorus, nitrogen and halogens are among the most common flame retardants.

- Plasticizers: Polymers without any plasticizer are normally rigid and do not have much flexibility, so they do not have enough properties for plastic processing for some applications. Therefore, they are added to the polymer to improve the production process and increase the ease of working with the compound. These softeners improve the elasticity properties, which are one of the most common polymer additives, which, for example, can be added to the phthalates used in PVC compounds. Cited.

- Stabilizers: These types of additives are added to the raw material of the polymer to increase the stability and longevity of the compound, and they are one of the most necessary additives because these materials prevent the color of the final product against ultraviolet rays.

Read more: What is a granule?

Types of compounds

Compounds are composed of different types and are used in different industries depending on their type and application. The most common ones include:

Polyethylene compound

Among the applications of compounds in industries, we can mention polyethylene compound, which is one of the most widely used and important compounds among other compounds and is one of the most used plastics in the world. Polyethylene (PE) is a light and versatile synthetic resin that is formed from the polymerization of ethylene and has properties such as high resistance to direct sunlight and various mechanical impacts, which in addition has ideal quality.

And it has a very reasonable price.There are different types of polyethylene compounds and each one is suitable for a set of applications depending on their properties. For example, high density polyethylene (HDPE) has higher tensile strength than other polyethylenes. It is often used in completely different applications than low-density polyethylene (LDPE), which has low tensile strength but good flexibility.

Ultra-high molecular weight (UHMW) polyethylene offers high-performance properties in applications such as the construction of heavy-duty pipes in the oil and gas industry, medical devices, waste disposal pipes, and bulletproof vests. Linear light polyethylene (LLDPE) has better mechanical properties and is mostly used in the production of polymer films with higher strength and tensile strength. In terms of polymer structure and density, medium density polyethylene (MDPE) is between heavy polyethylene and light polyethylene, and they are specially used in the production of large tanks for water storage, etc.

Polypropylene compound

Polypropylene compounds (PP) can be mentioned as another application of compounds in industries. This compound is a thermoplastic polymer and is the second most used plastic in the world and is used in many industries. This compound has properties such as low density, suitable corrosion resistance, high elasticity modulus, etc. This compound is used in various applications such as packaging of consumer products, pipes and fittings, plastic parts for various industries, including the automotive industry and Textiles are used.

Polycarbonate compound

This type of plastics are also known as engineering compounds and are suitable for applications that require high strength and high resistance to temperatures and chemical attacks. This type of plastics can be reinforced with glass fibers or mineral powders such as grape powder. Polycarbonate compounds (PC) have properties such as high flexibility, heat resistance, high impact resistance and flame resistance.

Polystyrene compound

Polystyrene compound (PS) is formed from the polymerization of styrene, which is a hard, rigid and transparent synthetic resin that is usually produced in the form of granules and is used in the manufacture of various plastic products due to its properties such as transparency and high resistance. From the use of granules in the industry, polystyrene is usually used in the packaging of food products, health and pharmaceutical products, disposable containers, automotive industries, toys, etc.

PVC compound

Another one of the most important applications of compounds in industries is PVC compound, which is very popular in many industries due to its properties and characteristics and is considered as the third most used plastic in the world. PVC compound is a thermoplastic material with high resistance, which is usually produced in the form of granules. PVC granules are used in a wide range of industries such as shoes, pipes and fittings, medical devices and wire and cable insulation, automobile manufacturing, etc., due to features such as high durability and strength, flexibility, resistance to UV rays, etc. is used.

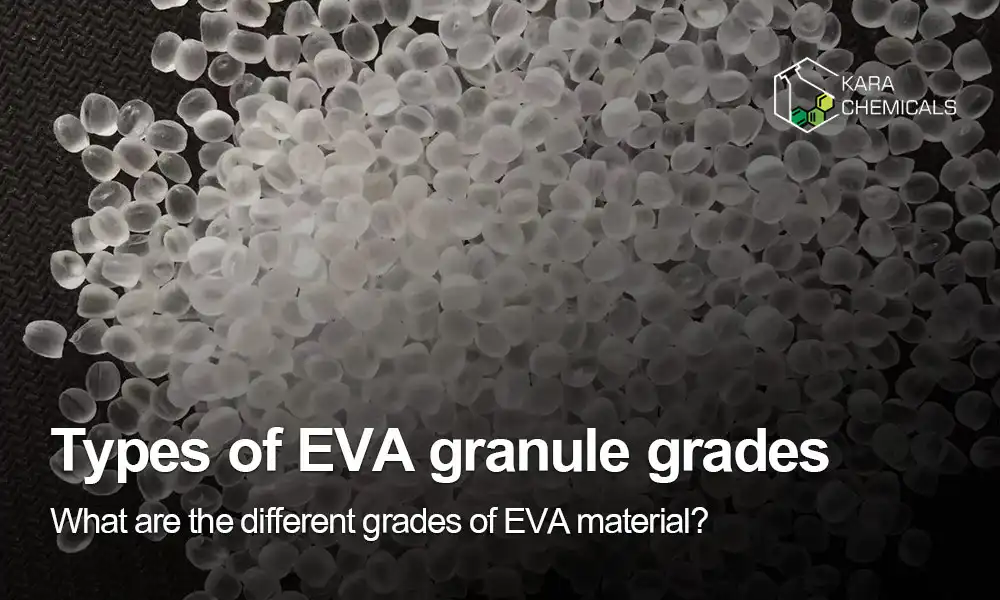

Compound EVA

EVA compound is made of a copolymer that is a combination of ethylene and vinyl acetate, which is used in many applications due to its excellent and numerous features. One of the most important applications of granules in industries is related to the applications of EVA granules. Due to its low density, it is very light, making it suitable for many applications such as the production of shoes and slippers, clothing, sports equipment, toys, etc. Other properties of EVA compounds include recyclability, high flexibility, resistance, high dimensional stability, etc.

The effect of application of granules in industries

The type of granule used in industries plays a fundamental role in the quality, efficiency and performance of the final product. The effect of granule type in its use in different industries is very impressive. Granules, defined as small, individual particles with sizes typically between 0.2-4.0 mm, vary depending on their composition, structure, and manufacturing process. These changes significantly affect their behavior and suitability for various industrial applications.

This effect occurs due to the inherent characteristics of the granule such as its size, shape, gender, structure and chemical properties. Each type of granules has unique properties and the application of granules in industries is different and each one is designed for a specific application.

The best manufacturers of granules

There are many companies that produce all kinds of granules and are in fierce competition with each other in the domestic market, and if they can produce a higher quality product and make the price more competitive, they can take the largest share of the market. Karachemicals is also considered one of the best granule producers. Karachemicals production granules include PVC granules and EVA granules, which are used in different grades for different applications. The products of this collection have a wide variety and are of very good quality. Due to the application of compounds in industries, this group is able to produce customized granules in different colors with high volume and supply quality products to domestic and country markets.

Read more: Properties of the granule

Which countries import granules?

There are many countries around the world that import granules due to the lack of domestic production or the need for variety in raw materials, and some of the largest importers of granules in the world are:

- China

- United States

- India

- Germany

- Belgium

- Italy

- Türkiye

- Mexico

- France

- Vietnam

As you saw in the article on the Application of granules in industries, Today, plastic compounds have become a better option than normal plastic due to their cheapness, better physical and chemical properties, and compatibility with the environment, and they are used in many industries, and the use of compounds in industries varies depending on their type. be The type of granule used plays a very important role in the quality, efficiency and performance of the product. By using the knowledge and experience of experienced experts and the use of quality additives and raw materials, Karachemicals Company is able to produce and supply PVC compounds and EVA compounds with high performance and physical and mechanical properties according to customer needs. Therefore, to choose the right granule, you can contact the experts of this collection through the website of this collection.

Additives are used to modify plastics to improve the properties of the raw materials and make them suitable for various applications.

Compounds are used in various industries such as automotive, electronics, household appliances, sports, toys, shoes and slippers, agricultural industry, medical industry, construction industry, etc.