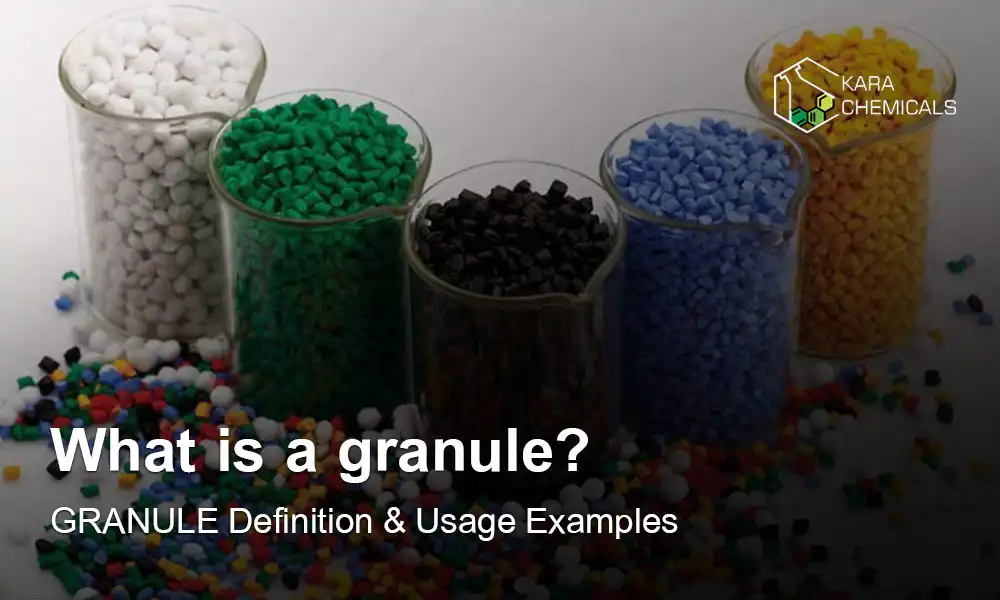

Granules are tiny particles created during the granulation process in the pharmaceutical manufacturing industry by the agglomeration of fine powders. Because of their improved flow characteristics, they are simpler to handle, dose, and combine evenly. Additionally, granules have better compressibility, which enables them to be packed into strong enough capsules or crushed into solid tablets. Granules also provide improved stability by shielding medication particles from degradation by decreasing their surface area. In general, granules are essential for creating pharmaceutical dosage forms that have stable contents, appealing exteriors, and higher stability. Follow us for more information about what is granule.

What is granule processing and production?

To this question, what is granule? Granulation is a vital unit process that is frequently used in the pharmaceutical sector to produce tablets and capsules. It entails using an agglomeration technique to increase tiny powders or particles. This creates free-flowing, dust-free granules that are easier to handle for the next processing steps, such as compression. In the production of pharmaceuticals, the granulation process has several uses. First off, it enhances the powder mixture’s flow characteristics. Poor flow properties in fine powders make them challenging to handle and dose precisely. These powders’ flowability is improved by granulating them, which makes it easier to mix them uniformly and guarantees constant content homogeneity across the dosage form. Granulation also encourages improved compaction qualities. In order to prevent breaking or crumbling during handling, packaging, and transportation, tablets and capsules need to have sufficient mechanical strength. What is granule? Granules have enhanced compressibility due to their larger particle size and stronger inter particle bonding, which makes it possible to produce tablets with the right amount of hardness, friability, and consistent drug content.

Granule production machine or extruder

In the manufacturing of pharmaceutical granules, extruders are crucial. They are made out of a cylindrical barrel, a die mechanism, and a spinning screw. The extruder uses compression, shearing, and kneading to process fine powder combinations. Granules become clumped together as a result. The extrudate is shaped by the die system into the appropriate shapes, like strands or cylindrical extrudates. To get the right granule size, more processing is frequently needed, such as sizing or milling. Extruders provide fine control over parameters such as temperature, pressure, and screw speed, enabling granule characteristics to be customized. It’s crucial to remember that additional equipment, such as fluid bed granulators or high-shear mixers, can be required based on the granulation method or formulation specifications.

What are the types of compounds?

Apart from ionic, covalent, and organic molecules, there are various other categories of chemical compounds that merit further investigation. Here are a few additional instances about what is compound:

- Metallic Compounds: Metal atoms bound by metallic bonds make up metallic compounds. These substances have qualities including brilliance, malleability, and high electrical conductivity. Iron oxide (Fe2O3) and sodium chloride (NaCl) are two examples.

- Molecular Compounds: Molecular compounds are a subclass of covalent compounds in which distinct molecules are formed by the covalent bonding of atoms. Usually, these compounds are made up of nonmetal atoms. Water (H2O) and carbon dioxide (CO2) are two examples.

- Inorganic Compounds: Compounds without carbon-hydrogen (C-H) bonds are referred to as inorganic compounds. They can be made up of covalent or ionic bonds and involve a variety of materials, including metal complexes, bases, acids, and salts. Examples are ammonia (NH3), sulfuric acid (H2SO4), and sodium chloride (NaCl).

- Organometallic Compounds: A family of compounds with at least one metal-carbon link is known as an organometallic compound. These substances are crucial to organometallic chemistry and catalysis because they frequently show distinctive reactivity. Methylcobalamin (CH3-Cbl) and ferrocene (Fe(C5H5)2) are two examples.

- Polymeric Compounds: Polymeric compounds are big molecules made up of monomers, which are structural repeats. These compounds can be produced by a variety of bonding methods, including ionic or covalent connections, and they can vary in complexity. Polyvinyl chloride (PVC) and polyethylene (a polymer comprising ethylene monomers) are two examples.

- Coordination Compounds: Also referred to as complex compounds, coordination compounds consist of a metal ion or atom in the center surrounded by ligands, which are molecules or ions that contribute electron pairs to form coordinate bonds. These substances are used in many fields, including materials research, medicine, and catalysis. The complex that forms between ammonia and copper (II) ions is known as [Cu(NH3)4]2+.

These are but a handful of the numerous varieties of chemical compounds that are in existence. Every variety possesses distinct qualities and attributes, and they are essential in different facets of chemistry and daily existence.

Read more: Properties of the granule

Applications of granules

What is a granule? Granules, also referred to as resin granules or plastic pellets, are essential to the electro-technical industry’s ability to produce electrical and electronic components. In these applications, plastics are selected because of their many qualities and capacity to meet the particular needs of the sector.

- Insulating qualities: Plastics are a great insulator, which is important for electronic and electrical components. Insulation is required to guarantee safe operation and to stop electric current from flowing between conducting parts. Polymers with low electrical conductivity and high dielectric strength, like polytetrafluoroethylene (PTFE), polypropylene (PP), polyvinyl chloride (PVC), and polyethylene (PE), are perfect for insulating applications.

- Temperature Resistance: When operating, electrical and electronic components frequently come into contact with high temperatures. Because of their high heat resistance, plastics can tolerate high temperatures without experiencing any noticeable deterioration or loss of their mechanical qualities. In situations where resistance to high temperatures is necessary, thermoplastics such as polyamide (PA), polyphenylene oxide (PPO), and poly ethers mide (PEI) are frequently utilized.

- Chemical Resistance: The performance and longevity of electrical and electronic components may be hampered by the harsh nature of chemicals. Because of their well-known chemical resistance, plastics are appropriate for uses where chemical exposure is predicted. For example, polytetrafluoroethylene (PTFE) shows remarkable resistance to a wide range of chemicals, but polyvinyl chloride (PVC) is resistant to numerous acids, alkalis, and oils.

- Flexibility and Durability: In the electro-technical sector, plastics are valued for their flexibility and durability. They may be molded into a wide range of sizes and forms, which makes it possible to produce intricate parts. Additionally, plastics ensure the durability and dependability of electrical and electronic devices by withstanding mechanical strains, vibrations, and collisions without suffering severe deformation or damage.

- Lightweight: The electro-technical industry benefits from plastics’ low weight. It makes electrical and electronic gadgets lighter overall, which increases their portability, ease of handling, and affordability when it comes to installation and transportation.

In general, there are many advantages to using plastic granules in the electro-technical business. What is compound? Plastics are a great material to use for electrical and electronic components, including cables, connections, covers, and switches, since they are lightweight, flexible, durable, and resistant to chemicals and high temperatures.

Determining factors of compound price

What is compound and compound price? a compound’s price is affected by a number of variables, including:

- Supply and Demand: A compound’s pricing is mostly determined by the fundamental concepts of supply and demand. The price of a compound tends to rise when demand is strong and supply is constrained. On the other hand, if there is more supply than there is demand, the price may drop.

- Cost of Raw Ingredients: A compound’s pricing may be directly impacted by the cost of the raw ingredients required to make it. The price of the compound may rise if the cost of the raw materials used in the synthesis or manufacturing process rises.

- Production and Manufacturing Costs: A compound’s price can be affected by the costs associated with its production and manufacturing, which include labor, energy, equipment, and facility costs. Complicated synthesis techniques or specialized manufacturing procedures may increase production costs, which will raise the compound’s price.

- Quality and Purity: A compound’s pricing may vary depending on its quality and purity. Highly pure compounds or those that adhere to strict quality requirements could fetch a premium price since they take more work and resources to attain and maintain.

- Market Competition: The level of competition in a certain market might affect a compound’s pricing. Competition can drive down prices if there are several suppliers or alternatives available, as businesses compete for customers. Conversely, a compound may fetch a greater price if there is no rivalry or if there are few alternatives that meet the high demand.

- Regulations and Intellectual Property: The cost of a compound can be impacted by both regulatory obligations and intellectual property rights. Adherence to regulatory requirements, such as safety or environmental standards, may increase manufacturing expenses and subsequently affect pricing. Furthermore, the owner of a chemical may be able to set the price if it is covered by patents or other types of intellectual property.

- Market Trends and Economic Factors: The price of compounds can be impacted by general market trends as well as economic factors including inflation, exchange rates, and general economic situations. Compound prices can be affected by changes in consumer purchasing power, production costs, and resource availability as a result of economic fluctuations.

The price of granules

What is granule and what can cost on granule? a number of variables can affect the cost of granules in bulk, such as:

- Granule Type: The market needs and production costs of various granule kinds differ. For instance, price ranges for plastic, rubber, and agricultural granules may change because of differences in the costs of raw materials, production techniques, and industry-specific market dynamics.

- Quantity Being Purchased: Larger quantities are usually involved in bulk transactions. Larger orders typically qualify for volume discounts from suppliers. As the order size grows, the cost per unit or weight of granules may go down. Suppliers frequently use tiered pricing schemes that are dependent on the quantity being bought.

- Quality Requirements: Granules may meet various requirements for quality, including those related to purity, particle size, chemical makeup, or certain functional characteristics. Granules of a higher caliber could cost more than ordinary or inferior alternatives. It is crucial that you let the suppliers know what standards you have for quality and ask about any possible price discrepancies.

- Market Conditions: Granule prices may be impacted by factors such as supply and demand dynamics. The availability of raw materials, production capacity, the state of the world economy, and industry trends are a few examples of factors that might affect pricing. It is a good idea to keep up with market developments in order to anticipate future price changes.

Read more: What is Granule EVA?

Bulk purchase of granules

In order to locate distributors or suppliers, you may want to take the following actions:

- Research: Look out possible distributors or providers of the particular kind of granules you’re interested in online. To locate pertinent contacts, you can use trade platforms, industry directories, and search engines.

- Get in Touch with Several Suppliers: Make contact with several suppliers and tell them of your needs, including the kind and amount of granules you require. Ask each supplier for a quote or more information about prices.

- Examine Offers: After obtaining quotations from several vendors, evaluate the costs, standards of quality, conditions of delivery, and extra services provided. It is imperative to take into account both the cost and the supplier’s credibility.

- Negotiation: If it’s feasible, haggle with the providers to obtain the best deal given your needs for large purchases. For larger orders, they might be prepared to offer discounts or better conditions.

- Take Other Considerations into Account: When choosing a supplier, it’s critical to take other aspects like quality, dependability, customer service, and delivery timeframes into account in addition to pricing. Leading PVC granules and EVA granules are produced by KaraChemicals Holding, a part of the “Hani Shimi Kara Plast” corporation, with impressive results. Their achievements can be attributed to their state-of-the-art apparatus, sophisticated polymer experts, and engineers working together in the laboratory.

Compared to powders or tiny particles, granules are smaller, more homogeneous solid particles. They are frequently employed in sectors including chemical manufacture, food processing, and medicine.

The procurement of materials, production efficiency, economies of scale, and manufacturing process optimization are factors that have an impact on the decrease in granule costs.

2 thoughts on “What is a granule? GRANULE Definition & Usage Examples”