The elastomeric polymer EVA (ethylene vinyl acetate) gives materials their soft, flexible properties. Its outstanding qualities include UV resistance, stress-crack resistance, low-temperature toughness, and waterproof hot-melt adhesive. Because of these qualities, it can be used in a wide range of industries, including construction, electronics, footwear, packaging, and automotive. Follow us for more information about properties of EVA granules and properties of EVA compounds.

What is EVA granules?

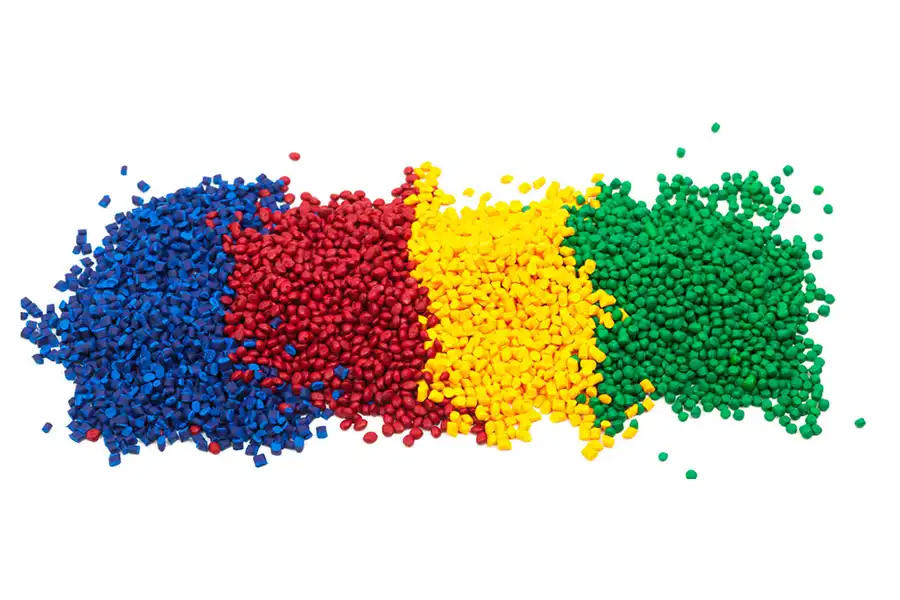

Rubber-like qualities can be found in EVA (properties of EVA granules), an elastomeric polymer that gives things their soft, flexible texture. EVA granules’ special blend of vinyl acetate and ethylene monomers produces a polymer with a number of advantageous properties. EVA stands out for having outstanding gloss and clarity. Because EVA materials are clear, light can pass through them with little interference. This feature is especially helpful in applications where aesthetic appeal or visibility are crucial. Apart from its optical characteristics, EVA presents remarkable mechanical attributes as well. It exhibits low-temperature toughness, which enables it to keep its resilience and suppleness in chilly conditions. Because of this characteristic, properties of EVA granules can be used in situations where materials must resist low temperatures without breaking or experiencing temperature variations.

An additional characteristic of EVA granules is their resistance to stress cracking. This indicates that when exposed to mechanical stress or tension, they are resistant to the creation and spread of cracks. Consequently, EVA materials exhibit a lower propensity to malfunction or degrade in these circumstances, thereby augmenting their robustness and endurance. EVA’s hot-melt adhesive and waterproof qualities are yet another advantageous feature. When melted and applied as an adhesive, EVA forms a solid bond that solidifies upon cooling.

Because of this characteristic, it is widely used in the manufacturing of different adhesives and sealants, especially in situations where water resistance is required.

Properties of EVA granules in packaging industries

Properties of EVA granules, a flexible material commonly used in packaging. It offers excellent flexibility, chemical resistance, and toughness, making it suitable for various packaging applications. EVA’s transparency allows for easy product identification, and its biocompatibility makes it safe for food, pharmaceutical, and medical packaging. EVA has a low sealing temperature, reducing energy consumption and minimising heat damage to packaged products. Additionally, EVA is cost-effective and widely available. The specific properties of EVA depend on the vinyl acetate content, which can be adjusted based on packaging requirements.

Properties of EVA compounds in textile industries

Properties of EVA compounds are useful in the textile industry because of their variety of characteristics. EVA is renowned for being flexible, which makes it simple to mould and shape for a variety of textile applications. It provides impact absorption and cushioning, improving the comfort of textile goods like padding materials and shoes. Additionally, EVA compounds have outstanding chemical resistance, which makes them strong and appropriate for textile applications that come into contact with chemicals or cleaning agents.

EVA also has thermal stability, which enables it to endure high temperatures in bonding and lamination production processes. Properties of EVA compounds are soft and have high adhesive qualities, making them suitable as coating materials or for sewing fabrics together. EVA chemicals provide performance and adaptability for textile applications overall.

Read more: What is Granule EVA?

Properties of EVA granules in the clothing industry

Properties of EVA Granules have a number of qualities that make them appropriate for use in a range of apparel-related applications. In the apparel sector, EVA granules have the following important characteristics:

- Softness and Flexibility: Because EVA granules are flexible and soft like rubber, they can be used in garment applications where comfort and ease of movement are essential. They can be used to make flexible and pliable parts like cuffs, shoulder straps, and waistbands.

- Cushioning: EVA granules offer superior comfort and impact absorption through their cushioning qualities. This quality is useful for apparel products where comfort and impact protection are crucial, such as sportswear, protective gear, and padded coats.

- Lightweight: The low weight of EVA granules contributes to the total weight reduction of garment items. This is especially useful for footwear, outdoor apparel, and sportswear since lightweight materials enhance performance and mobility.

- Resistance to Moisture: EVA granules are well-suited to withstanding moisture and water absorption. This feature is helpful for garment applications like swimwear, rainwear, and outdoor garments where moisture management and rapid drying are crucial.

- Thermal Insulation: The thermal insulation qualities of EVA granules aid in the preservation of body heat in chilly climates. Because of this, they can be used in insulating layers, thermal pants, and winter apparel.

- UV Resistance: EVA granules defend against the sun’s harmful effects by showing good resistance to UV rays. This characteristic makes sun protection apparel, such as hats, caps, and coats, useful.

- Adhesive Compatibility: Using adhesives, EVA granules are readily adhered to a variety of substrates. Their use in clothing applications where laminating, bonding, or joining different layers or components is required is made possible by this characteristic.

- Dye ability: A large variety of colours can be used in clothing design since EVA granules are simple to dye. This characteristic makes it possible to design colourful and visually appealing shoes, purses, and accessories.

- Durability: EVA granules have a reputation for being resilient to abrasion, wear, and tear. The properties of EVA granules help clothing items last longer by guaranteeing that they can resist frequent use and continue to function as intended over time.

Properties of EVA compounds in other industries

The following extra characteristics of the properties of EVA compounds make them appropriate for use in a variety of industries:

- Agriculture and Horticulture: Because of their superior UV resistance, flexibility, and durability, EVA compounds are employed in agricultural and horticultural applications. To keep plants wet, shield them from UV rays, and promote crop development, they are used in agricultural mulch films, greenhouse films, and crop coverings.

- Consumer Goods Industry: Because of their flexibility, softness, and resilience to impact, EVA compounds are used in this sector. To offer comfort, safety, and durability, they are used in toys, foam grips, handles, and ergonomic goods.

- Furniture and Upholstery Sector: Due to their cushioning qualities, suppleness, and flexibility, EVA compounds are used in the furniture and upholstery sector. They give comfort and aesthetic appeal to furniture items by being used in upholstery, pillows, and padding.

- Marine sector: Because of their water resistance, buoyancy, and durability, EVA compounds are appropriate for the marine sector. They offer protection, buoyancy, and slip resistance and are used in marine applications such as boat fenders, buoys, boat decking, and marine flooring materials.

- Electrical and electronics sector: Because of their superior electrical insulating qualities, EVA compounds are used in the electrical and electronics sector. To guarantee dependability and safety, they are used as insulating materials in cables, wire harnesses, connections, and electrical components.

- aircraft industry: Properties of EVA compounds are appropriate for several aircraft applications due to their lightweight, flexible, and temperature-resistant qualities. They can be used in gaskets, insulation, padding, and aeronautical components. It is noteworthy that the particular composition and attributes of EVA compounds may be customised to fulfil the particular demands of every sector and use case. Based on the demands of a particular sector, manufacturers and suppliers can offer additional direction and choices for customisation.

Read more: What is the application of EVA in industries?

Advantages and disadvantages of using EVA granules

Advantages of EVA granules

- Versatility: Because EVA glue can attach a variety of materials, including wood, cloth, paper, plastic, and foam, it has a wide range of uses. It is appropriate for usage in several sectors due to its adaptability.

- Quick Drying: EVA glue dries quickly, allowing for more productive production procedures. It cuts down on waiting and assembly times by creating strong ties in a matter of minutes.

- Transparency: EVA glue leaves a transparent or translucent finish behind when it dries. This feature improves aesthetics; therefore, it’s especially useful for crafts or tasks where a clean connection is required.

- User-Friendly: Applying and using EVA glue is a simple task. Because it comes in a variety of forms—sticks, pellets, or liquid—application techniques may be tailored to the specific needs of the project.

- Non-Toxic: Because EVA glue is non-toxic when dried, it is typically regarded as safe for usage. Because of this functionality, it may be used for projects that include kids or where safety is an issue.

Disadvantages of EVA granules

- Sensitivity to Heat: The bond may weaken or fail as a result of EVA glue’s sensitivity to heat. For applications that are subjected to high temperatures or extended heat exposure, it is not advised.

- Limited Water Resistance: EVA glue is not totally waterproof, although it has a respectable level of moisture resistance. Long-term water exposure can degrade the bond, rendering it unsuitable for uses where strong water resistance is required.

- lesser strength: EVA glue could have a lesser shear and tensile strength in comparison to certain other adhesives. For heavy-duty applications or those requiring exceptionally high bond strength, it might not be the best option.

- Durability: Under stressful or harsh circumstances, the strength of the connection formed by EVA glue may deteriorate over time. This can call for reapplication or reinforcement on a regular basis. Properties of EVA Compound, or EVA Granule, is a compound consisting of two weights, 18% and 28%. These compounds’ derivative copolymers are widely used in the production and packaging of plastic products. Ten percent to forty percent of the weight of EVA sheets is made up of vinyl acetate. Properties of EVA Compound or EVA Granule’s main applications include making EVA glue, slippers, sandals, sports gear (like skis, boots, and tatami), kid-sized foam labels, artificial flower manufacturing, and its use in the plastic, textile, packaging, and other industries. KaraChemicals Company is one of the leading producers of EVA compound or EVA granule.

Flexibility, softness, transparency, strong adhesion, low-temperature resistance, chemical resistance, UV resistance, impact resistance, thermal stability, and electrical insulation are just a few of the many characteristics of EVA (Ethylene Vinyl Acetate) granules and compounds. Because of these characteristics, EVA can adapt, cushion, bind with various materials, resist chemicals and UV rays, survive low temperatures, absorb impact, keep its stability, and provide electrical insulation. Nevertheless, the particular characteristics may change depending on the application and formulation.

Granules and compounds made of EVA (ethylene vinyl acetate) may normally be used without risk in situations where they come into contact with food or skin. For applications involving food contact and skin contact, it is crucial to confirm that the particular EVA formulation complies with all applicable laws and regulations.

3 thoughts on “Properties of EVA granules: Properties EVA Ethylene-vinyl acetate granules”