Stabilisers and lubricants are crucial additions for all PVC materials, while plasticizers are also included in flexible PVC. Fillers, processing aids, impact modifiers, and colours are other additives that could be employed. To change and improve the qualities of PVC (polyvinyl chloride) formulations, a variety of chemicals are added. Although PVC is a flexible polymer, its pure form may be hard and brittle. Additives assist in overcoming these restrictions and enhance PVC’s flexibility, workability, stability, and other qualities. These are some of the main additives that are used in PVC compositions. The intended qualities, processing requirements, regulatory compliance, and end-use applications of the PVC products all influence the choice and mix of additives.

Why additives matter in PVC manufacturing?

In its purest form, PVC is a stiff and brittle polymer. PVC formulations often include additives to change the material’s characteristics and improve its suitability for different uses. For instance, stabilisers are used to guard against deterioration, impact modifiers are added to boost toughness, and plasticizers are used to increase flexibility and workability. Manufacturers may modify the characteristics of PVC to fulfil certain needs by adding additives. Overall, additives are critical to the production of PVC because they enable the customization of PVC characteristics, increase processability, reduce costs, improve stability, give aesthetics, and guarantee regulatory compliance. To achieve the intended performance and satisfy the unique needs of PVC products, additives must be carefully chosen and formulated.

Types of additives and their functions

Each kind of additive has a distinct purpose and is used in a variety of sectors. There are several additional specialised additives that are used in various sectors and applications to improve certain qualities or meet particular needs. The final product’s unique requirements and intended performance will determine the additives’ choice and mix.

In-Depth analysis of key PVC stabilizers

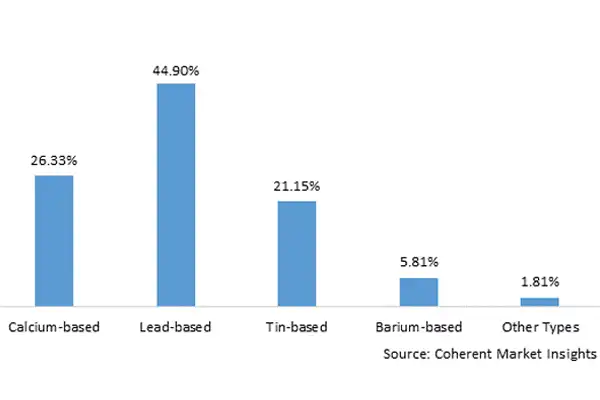

A comprehensive study of the market size and demand for PVC stabilisers in major regions and nations is also included in our research. Along with a current evaluation of the market’s prospective prospects and difficulties, it also provides a thorough review of the product’s price structure. Our research also contains critical market trends and insights from a thorough examination of the numerous PVC stabiliser uses. This aids decision-makers and company owners in developing educated business plans. Finally, a full examination of the regulatory structure controlling the PVC stabiliser industry is included in the research, enabling businesses to stay ahead of any possible legal concerns.

READ MORE: What are additives in PVC?

Enhancing PVC flexibility: The role of plasticizers

A plasticizer with at least 15 phr is needed to make PVC flexible. Less than this triggers antiplasticization, which actually makes things more rigid. To get the necessary qualities, such as tensile and tear strength or low-temperature flexibility, plasticizers may be employed alone or in combination.

By lowering PVC’s glass transition temperature (Tg) and raising its general ductility, plasticizers play a critical role in improving the material’s flexibility. PVC is a stiff and brittle polymer in its pure state, but the addition of plasticizers turns it into a flexible and adaptable substance. There are many different plasticizers for PVC, including those based on phthalates, adipates, phosphates, or citrates.

According to the individual application requirements, such as desired flexibility, mechanical qualities, chemical resistance, and regulatory concerns, the right plasticizer should be chosen. To maintain the ideal balance between flexibility, mechanical strength, and other features of the PVC material, it is crucial to take into account the type and concentration of plasticizers. An overdependence on plasticizers may eventually result in problems like plasticizer migration, diminished dimensional stability, or deteriorated mechanical qualities.

Impact modifiers: making PVC tougher

In order to satisfy the physical property requirements of stiff components, impact modifiers are essential additions for boosting flexibility and impact strength. At room temperature, several unaltered polymers, including stiff polyvinyl chloride (PVC), polystyrene (PS), and styrene acrylonitrile (SAN), are brittle. Impact modifiers are additives that may greatly improve PVC’s (polyvinyl chloride) toughness and impact resistance.

Pure PVC is a rather fragile polymer that is quickly broken or fractured when put under abrupt loads or impacts. Impact modifiers function by increasing PVC’s ductility and capacity for absorbing energy, which enables it to sustain impacts without breaking or cracking. Depending on the particular application requirements and the required PVC product qualities, the right impact modifier should be chosen. To retain other important characteristics of the material while achieving the appropriate amount of toughness, the ideal impact modifier and its concentration in the PVC formulation should be carefully selected.

Improving processability with PVC processing aids

Processing aids are very necessary for PVC-U processing to be done correctly. Since the polymer would decay at almost the same temperature required to process the material, processing without essential additives like lubricants and heat stabilisers would probably lead to degraded polymer for every single component. Processing aids are also required to boost the melt’s suppleness and stretchability.

This is crucial because it will determine how well the material can shear and degrade the PVC compound particles to intensify fusion. Because PVC synthesis is distinct from that of the majority of other polymers, the phrase “degree of fusion” is not often used to describe numerous plastics. Vinyl chloride, the monomer used to make PVC, is insoluble in PVC. As a consequence, during the polymerization process, PVC bundles into particles that separate from the monomer solution, resulting in a powdery final product.

This unusual response has advantages as well as drawbacks. One advantage is that monomer elimination during polymerization occurs spontaneously, producing products with extremely low monomer contents that are perfect for use in food and medicine. Processing aids are necessary since this powdered material might be problematic to handle during processing. Even with proper processing aids, PVC particles may readily bundle and result in poor material fusion if the processing circumstances are not ideal.

Adding color to PVC: The world of colorants

Plastic colourants help create a product’s image and enhance its use and quality, in addition to adding colour to our lives. The ornamentation is where the impact of colour is most apparent. Use colour and lustre to expertly design an impression, such as a feeling of elegance and dignity, in the context of cosmetics, household appliances, and automotive interiors. Colour also contributes to identification. As an illustration from everyday life, let’s say that the plastic lids for hot beverage bottles are all equally orange in colour. As a result, we can recognise hot liquids right away. Additionally, colours are chosen in accordance with international norms for unmistakably identifying items during construction or in an emergency, such as blue for water pipes and yellow for gas pipes. Additionally, colours may be utilised to shield contents. For instance, a product’s exterior may be painted black to protect its contents from UV radiation and screen the object from degradation.

READ MORE: What is UPVC

The science behind PVC additive interactions

Understanding the chemical and physical interactions that take place between the additives and the PVC polymer matrix is essential to understanding PVC additive interactions. For PVC granule products to be formulated with the appropriate characteristics and performance, it is essential to comprehend the science underpinning additive interactions with PVC. Solubility, compatibility, molecular interactions, synergistic or antagonistic effects, processing effects, and long-term stability are just a few of the variables that must be taken into account. Manufacturers may create PVC formulations that fulfil particular needs for different uses by researching and improving these interactions.

Discover the benefits of plasticizers for increasing flexibility, impact modifiers for boosting toughness, stabilisers for boosting durability, and processing aids for maximising manufacturability.

In its pure state, PVC exhibits stiffness and brittleness. However, PVC formulations undergo modification through the addition of various additives to enhance its properties for diverse applications. Stabilizers safeguard against deterioration, impact modifiers enhance toughness, and plasticizers increase flexibility. Additives play a crucial role in PVC production by enabling customization of characteristics, improving processability, reducing costs, ensuring stability, providing aesthetics, and ensuring regulatory compliance. Careful selection and formulation of additives are essential to achieving desired performance and meeting the specific requirements of PVC products.